Molt

Taylor’s Coot

Amphibian

and Other Airplanes

Low,

folding wings give Coot pilots superb water maneuverability as well

as the ultimate in versatility.

TEXT AND PHOTOS

BY RICHARD STEEVES

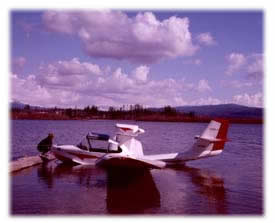

Coot builders don’t need to worry about building or damaging wing-tip floats. Molt Taylor was able to avoid using such accident-prone appendages by mounting the wings on the ends of strong, water-immersed sponsons, thereby allowing the buoyancy of the wing roots to provide lateral stability and to greatly reduce the likelihood of accidental capsizing in rough water. The low wings provide two other advantages: They allow the engine to be mounted low as well, and they protect the propeller from water spray.

Designed for Versatility As Well As Safety

Right after WWII Molt Taylor began to design a 2-place amphibian for commercial production. Called the Duckling, its plans were soon shelved when Molt turned all his energy toward the development of his famous Aerocar, a roadable aircraft with folding wings. Twenty years later, when Molt returned to his Duckling drawings, he naturally incorporated the wing-folding feature from the Aerocar into a more modern amphibian called the Coot.

During my first visit to Molt’s shop in 1973 (when I took the photo below), I was fascinated by the elegant way this sophisticated aircraft could be stored and moved from shop to airport and back with so little fuss. Since then I have used the same method many times, and I have often wondered why this utilitarian feature hasn’t been integrated into the design of most aircraft.

The Coot is trailered tail-first with the stabilizers and elevators

folded down to make room for the folded wings, which just barely fit

underneath the propeller. Coots have been towed for thousands of miles

this way.

Expert Advice

During my visit with the designer I heard about Don Avery, a retired Professor of Mechanical Engineering at the University of Hawaii. Before deciding to build a Coot, he spent most of his spare time for 2 years testing the wing ribs and spars and their attachment to the hull. As a result of these tests Don advised all Coot-builders to glue at least 2 vertical spruce stiffeners onto every diagonal wing rib, as shown below.

Don

Avery’s

wing ribs were dramatically strengthened by adding two vertical

stiffeners that weighed less than half an ounce.

Later, when I visited Don at his home in Kaneohe, I discovered his humorous side as he posed holding an inverted broom into the control stick socket! I also found him to be a most instructive teacher, for he demonstrated not only the importance of the rib stiffeners but also how to use the wings as jigs for accurate placement of the main spar bulkhead in the heart of the Coot, called "station 96".

The

broom in Don’s

right hand reveals a professor with a sense of humor. Note how

the wings serve as jigs for precise hull frame location

before glassing them in place.

A Quarter of a Century Passes

Even though Don’s suggestions led to the only significant change to be incorporated into an otherwise very complete set of plans, it soon became apparent that the builders’ construction notes needed to be edited, and the builders needed a newsletter for more effective communication. In 1975 I offered to look after both in exchange for $100. worth of fiberglass parts, and Molt struck a bargain. Over the next 25 years I wrote a newsletter to about 120 subscribers every 2 months. During that time I visited and described many Coot projects, built a collection of relevant photos, and eventually wrote a book that summarized the history and development of the Coot, called The COOT Story.

In Chapter 9 of that book I identified 57 Coots that had left the nest and taken to the skies. Most of them (39 in USA, 15 in Canada and 3 in New Zealand) flew quite well during a grand total of over 9000 hours. Several of us have enjoyed long trips in our Coots, especially the Canadians, and Paul Trudel from British Columbia has crossed the continent 3 times!

In November 1995, a few days after a wonderful party and induction into the Hall of Fame by the EAA, Molt suffered his third and fatal stroke. Mrs. Taylor continued to send out Coot plans for a while, but later passed the torch to me. Since then I have up-graded the construction manual, improved the clarity of the 177 drawings, converted some of them to CAD, and added a set of 99 construction photos (originally taken by Molt).

Typical Builders and their Expectations

I sell between 8 and 10 sets of plans per year to people who have usually done their research well. They are often knowledgeable in some aspect of aviation or have general mechanical skills. They want to get started without having to invest thousands of dollars up front to purchase a kit. They understand that the Coot is a 2-place amphibian because its simple design has C.G. limits. Molt started with 2 very strong central bulkheads (at stations 96 and 127) and hung the landing gear and wings on the ends of them, the engine above, the people in front, the fuel between and the tail behind. The bulkheads are built individually and are glassed into their respective locations in a fiberglass hull. The latter, along with the foredeck, tail fairing, cowling, canopy and other fiberglass parts with compound curves can be purchased for $3,175. from Ken Welter (Camas WA), who has all of Molt Taylor’s original molds. Builders can expect to invest about $15,000. for all materials and parts (but excluding engine and prop costs) over about 3,000 hours of building time.

View breakaway diagram of Coot.

Current Choices

There are still plenty of choices for today’s builder. While Molt initially recommended the Franklin 6-cylinder (180 to 210 HP) engine because of its simple bed mount and shimmy damper, some builders have successfully used Lycoming, Continental and even the Mazda 13B engine. The landing gear legs are often of Molt’s design, but modes of retraction assistance vary from electric or hydraulic to pneumatic. Four builders have modified Mooney gear legs to retract outwards into the wings. Canopies have ranged from gull-wing or fold-over Lake-type to sliding side-covers or even a modified Defiant bubble canopy.

Perhaps the most popular recent option is the installation of auxiliary sponsons. Built from unicellular polystyrene foam and 5.5 feet long by 13 inches wide, they replace the spray rails on each side of the hull. Not only are the sponsons more effective (than spray rails) at keeping water spray away from the propeller under adverse loading conditions, but they provide more flotation and a wider hull to mount the bow wave, thereby improving what was already spectacular step-taxiing maneuverability. Two additional benefits are easier entry and exit from the cabin and slightly increased (7-10 mph) airspeed at 65% cruise power. They can be built to be either bolted or fiberglassed in place. It appears that the majority of new builders will use them, especially if they anticipate having an empty weight over 1500 pounds.

The auxiliary sponsons for this beautiful Coot, built and photographed

by John Hessler (Groveland CA) follow the hull contour and are bolted

in place. In one timed experiment with and without the auxiliary sponsons

but loaded with two adults, the time to mount the bow wave was reduced

from 15 to 9 seconds with the sponsons on.

Molt Taylor’s Other Aircraft

While there are more flying examples of the Coot than any of Molt’s other designs, the single-place Mini-IMP is more popular in terms of the total number of plans sold, and is more innovative as well. Like the Coot, it has folding wings and a pusher propeller, but the similarity ends there. The Mini-IMP is built mostly from aluminum, the tail feathers are mounted as an inverted V, and the propeller is mounted on the end of a long shaft that is coupled to the centrally located engine. Perhaps its most novel feature is the use of full-length flaperons behind a GA(PC)-1 airfoil that can be adjusted in flight to "tune" the wings for optimal performance during climb, cruise or descent. Gary James (P.O. Box 2011, Weatherford TX 76086) has very effectively taken over builder support, plans and newsletter for this design.

The diminutive size of the Mini-IMP is demonstrated in this photo of Mrs. Taylor standing beside it, taken by the designer.

Molt did not sell plans for any other designs, but he certainly enjoyed exploring new ways to make efficient aircraft. In order to reduce building costs he conceived of the idea of TPG (Taylor Paper Glass), a system in which polyester resin was used to coat and seal a laminated solid fiber card board after the individual parts had been cut out with a knife or hand shears. Once the paper parts were sealed, they were covered on both sides with a very dense fiberglass cloth to produce a 3-layer laminate. These parts were then assembled into the basic aircraft structure by stapling them to wood battens followed by bonding with resin and fiberglass cloth to form strong joints that could easily be sanded smooth. Molt and his associate, Jerry Holcomb, wrote a booklet about TPG, because it was relatively inexpensive, safe to work with, easily drilled, sawed, sheared, stapled, laminated and shaped in one plane of curvature.

Molt also recognized the need for a controllable propeller on his pusher aircraft. Since none was available that could be adapted readily to the long shaft and Flexidyne coupling used on these planes, Molt eventually designed and built his own "Micro-Prop" propeller. Made from Kevlar blades mounted on a unit that resembled the tail rotor mechanism of a helicopter, it provided not only controllable pitch, but it was fully reversible, allowing his aircraft to land and stop in a relatively short distance.

Molt’s last innovative aircraft was the Bullet. He used the best features of his earlier designs, including the GA(PC)-1 airfoil with full length flaperons and optimal adaptations of TPG. With significant assistance from Jerry Holcomb, Molt wound up with a beautifully contoured fiberglass shell that gave no impediments to the smooth passage of air over it. Aside from being very sleek with the smooth lines of its name, it was a practical airplane. The wings had a high angle of attack, allowing it to get in and out of small airstrips in the mountainous terrain of the Northwest. Molt kept the nose low (tail high) for maximal forward visibility during low-speed take-offs and landings. This allowed him to mount the propeller on the tail and give clean airflow over the fuselage and wings. Finally, its reverse pitch capability shortened the ground run after landing.

By

sweeping the wings forward and placing the Revmaster engine at the

front of the

plane, Molt assured

that variations in pilot/passenger

weight would not disturb the Bullet’s perfectly placed center of

gravity.

This combination of features gave exceptional performance. For example, compared with a 115 hp Cessna 152 of similar empty and gross weights (1000 and 1600 lb., respectively), the 70 hp Bullet took off in less distance, climbed faster on less power, went further on the same amount of fuel, and had a faster cruise speed.

This is not to imply that the Bullet performed flawlessly. As with most prototypes, there were some annoying glitches, such as difficulties with the long Flexidyne coupling between the engine in front and the propeller at the tail, and some trouble retracting the main gear, which were left extended during the 50 hours of flight-testing. Eventually the owner, Jim Berry, donated his Bullet to the Oregon Air Museum in Eugene, where it remains on display.

Molt’s Legacy

In many ways Molt Taylor lived ahead of his time. Like some of our modern architects, his genius exceeded the quality of materials or controls available to make his ideas work well. The Aerocar was conceived long before the FAA could imagine coping with air traffic that might have resulted from a roadable aircraft in every garage. Ironically, the Coot was his most popular design, in terms of the number of aircraft flying, yet it was the simplest in concept. However, there are still enough well-conceived ideas buried in that simple design to keep it popular long after its inception 30 years ago, and the Coot remains the only amphibian with a folding float-wing.

COOT Amphibian

|

SPECIFICATIONS |

STANDARD FEATURES |

|

Height 8 ft. |

Folding wings |

|

Length 22 ft. |

Folding stabilizers |

|

Wingspan 36 ft. |

Manual gear retraction |

|

Width 8 ft. (wings folded) |

Non-retractable water rudder |

|

Tail span 9.7 ft. |

OPTIONS |

|

Tail span 9.7 ft. |

Auxiliary sponsons |

|

Wing chord 5 ft. |

Hydraulic gear retraction |

|

Wing area 180 sq. ft. |

Pneumatic gear retraction |

|

Empty weight 1450 lb. |

POWERPLANT CHOICES |

|

Gross weight 1950 lb. |

Franklin 180 &endash; 220 HP |

|

Fuel capacity 28-40 gal. |

Continental 220 HP |

|

Cabin width 44 in. (2 seats) |

Lycoming 200 HP |

|

PERFORMANCE |

|

Cruise speed 110 mph |

|

Stall speed 48 mph |

|

Range 300-600 n.m |

|

Rate of climb 800 fpm |

|

Takeoff distance 800/1000w |

|

Landing distance 1000/900w |

|

Service ceiling 13,000 ft |